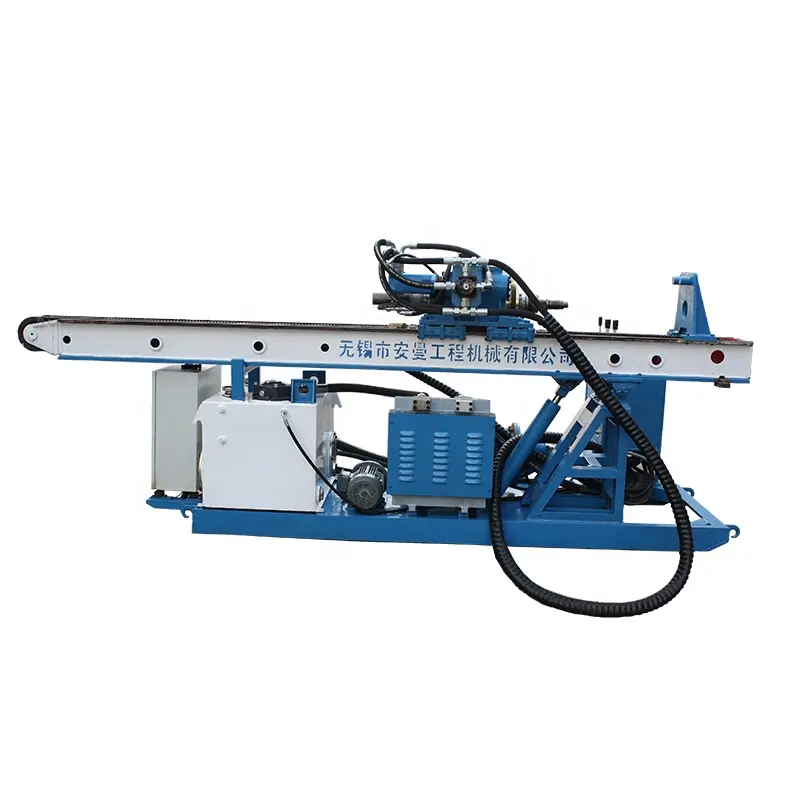

【Construction Case】MXL-150D6 Drilling Rig in Singapore

Basic information introduction

Location (province): Singapore

Location (city): Singapore

Drilling rig model: MXL-150D6

Drill tool configuration: 89 triple rotary spray drill pipe

Process type: rotary spray reinforcement

Construction technology: double rotary spray

Stratum condition: 0-10 m yellow mud (containing a small amount of sand, slightly sticky, soft)

Construction Angle(°): 90

Pore size (mm): 800

Hole depth (m): 7.72

Construction efficiency (min): 80

Pure drilling time (min): 6

Introduction to construction technology

1、Mark the hole point, the whole site, dig slurry tank, lay slurry pump and lay steel plate.

2、The machine moves to the hole point, each leg support the ground, to the left and right and perpendicular.

3、The background is ready to hit 7.72 meters to the bottom with water and gas, and the drilling machine feeding parameters (water pressure: 20 MPA, air pressure: 0.69 MPA, water flow 65 L/min, footage degrees 1-2 m / min, speed 15 r/min).

4、Machine parameters during lifting (water-ash ratio example 1:1, slurry pressure 25 MPA, pressure 0.69 Mpa, slurry flow 56 L/min, lifting speed 9cm / min, speed 12 r/min).

5、For each meter of the drill pipe, the outer wall of the drill pipe shall be cleaned with water gun, the mud pump shall be opened when the mud in the drainage tank is more than half, and mud turbulence is prohibited at the site.

6、When the drill bit is 1.5 meters from the ground, the suction mouth is closed to open the suction mouth is washed for about one minute, the high pressure pump pressure is gradually reduced by 1 MPA, and the drill pipe is lifted from the ground, and the nozzle can be observed and cleaned.

7、Move the machine to enter the next hole position preparation.

—— Anman drilling rig sales service: Sun Chong

Journey of drilling rig

1、Package

Meet the five major requirements of transportation and packaging:

① Adapt to the different characteristics of different commodities, special commodities independent packaging;

② Adapmeet the requirements of different transportation modes;

③ Consider the legal provisions of the relevant countries and the special requirements of the customers;

④ Easy for transportation and identification;

⑤ Save money on packaging costs.

2、Sign

Complete signs, posted eye-catching:

① transport mark;

② Indicative mark;

③ Warning signs;

④ Weight and volume mark;

⑤ origin sign

3、Transport

The role of Marine cargo transportation:

①Marine cargo transportation is the main way of international trade transportation;

②Marine cargo transportation is one of the important channels for the country to save foreign exchange payment and increase foreign exchange income;

③The development of Marine transportation industry is conducive to improving the country's industrial structure and the structure of international trade export goods;

④The Marine transport fleet is an important reserve force for national defense.

4、Arrive

At present, Anman rig has been exported to Singapore, the Philippines, Malaysia, Thailand, Vietnam, Bangladesh, Argentina, the United Kingdom, Canada, Africa and other countries and regions, to provide you with "buy at ease, comfortable use" products and intimate services.

03-29-2023

.jpg?x-oss-process=image/resize)

04-11-2023

【2023 "Anman Rig" Cup】The 6th Sheep's Point Basketball League has started!

04-11-2023

【2023 "Anman Rig" Cup】The 6th Sheep's Point Basketball League has started!